English

Suomi

Svenska

Automatisation

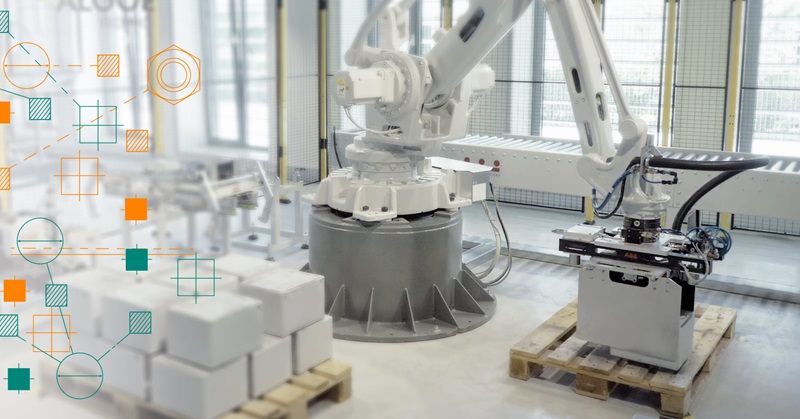

Automated production improves overall equipment effectiveness considerably.

In practice, this means it:

- minimises employee-related non-productive costs resulting from breaks, sick leaves and other working time interruptions

- expedites product turnaround time by several days

- boosts production volume by dozens of percentage points

- improves delivery reliability by several percentage points

- as much as doubles profitability

- makes it easier to adapt production to demand

- reduces sick leave and accidents, makes the work lighter and improves the meaningfulness of the work

- produces products of excellent, uniform quality and minimises the number of notices of defects.

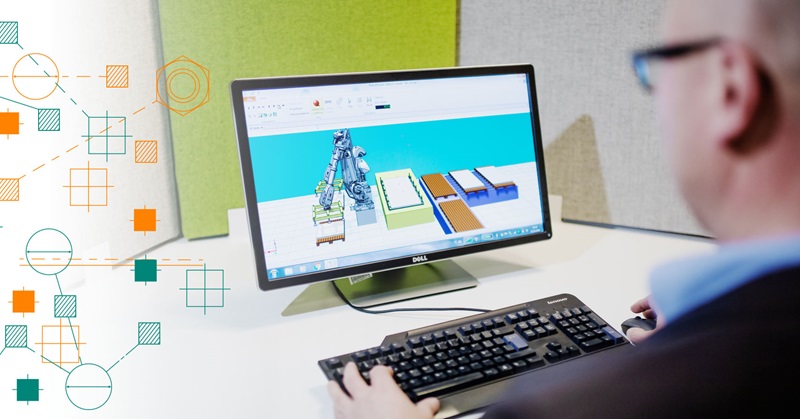

An efficient automation system performs on the factory floor exactly the way described in the quote. It is designed, tested and installed according to schedule. When a cell or production line is activated, it stacks, assembles, tests and packs the required number of pieces in the time promised. This guarantees that the calculated repayment term is achieved.

Our implementation support ensures appropriate user training for your production employees. Our efficient automation system includes its easy integration with the production control systems.